in the Korean War

from

An Aerial Photographer’s Point of View

by Wayland Mayo

INTRODUCTION TO THE B AND RB-29

The B-29, with it’s awesome destructive power,

is legendary. We all consider the atomic drops on Hiroshima and Nagasaki

as being the most devastating of all. However, the incendiary attacks

on Tokyo, Nagoya, and Osaka actually caused greater damage than both

atomic attacks. The M-69, M-47, and M-15 magnesium thermite incendiaries

would have eventually leveled every city in Japan. Targets in Korea

were far more difficult to hit due to the dispersion of enemy troops.

Bridges were difficult to hit, with most bomb runs straddling the bridge.

Airfields that were hit one day were repaired for use the next day.

We did not possess the “smart bomb” that is so effective today.

So we pretty well know about the B-29 accomplishments, but what about

the RB-29. This story contains my personal observation and evaluation

of the RB-29. We will begin with a look at production problems with

the B-29, along with some technical specifications. Then we will take

a look at the purpose of the RB, and the camera configuration.

The first production B-29 rolled off the assembly

line at the Boeing plant in Wichita in 1943. Numerous problems almost

kept it from ever being produced. The R-3350 engine malfunctioned

repeatedly, mostly from overheating and fires. The overheating was

occurring around the exhaust valves of the rear row of the 18 cylinder

engine, causing complete engine failure.

By installing 14 new engine baffles, cooling air was directed on the

rear exhaust valves. The fixed cowl flaps on top were made operable.

Also oil was redirected to obtain a better flow to the valves that

were overheating. So the B-29 was born with a multitude of problems

, and many accidents occurred. The R-3350 was always a “leaker”.

Preflight procedures during pressure checks almost always found an

oil leak.

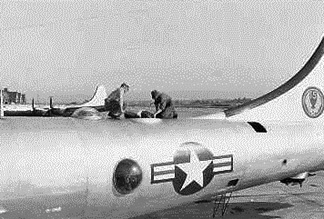

Ctsy Aero Publishers, Inc. (Boeing 62450/BW11392)

The pressurization system was unique in that the front

compartment and the rear compartment were both pressurized. Since the

two compartments were separated

By the two huge bomb bays, they were connected by a 34 inch tube, just

large enough for an airman to crawl through. The cabin had a supercharger

with a flow capacity of 25 pounds per minute, which brought the inside

atmosphere down to 8000 feet at an altitude of 30,000 feet.

The first B-29’s produced had twelve 50 caliber

machine guns, plus a 20 mm cannon mounted in the tail. The cannon was

later discontinued and only a few were produced. The gunnery system

had a central fire control which used an automatic computer to correct

for airspeed, range, altitude, and temperature. It was sophisticated,

even by todays standards. This system allowed any gunner, except the

tail gunner, to take over more than one power driven turret. Gunners

did not have actual contact with the guns, as they were fired from remote

stations using a sighting device.

Ctsy. Aero Publishers, Inc.

(Boeing-Wichita BW24357)

End of Chapter 01 — Go to Chapter 02

Chapter — 01 — 02 — 03 — 04 — 05